Line specifications:

S / N | item | Contents | Remarks |

1 | Line dimensions | L6600mm (length) * W3600mm (width) * H1950mm (height) | For reference only |

2 | Gross line weight | Total line weight ≤ 5000KG; Floor wiping load ≥ 500KG / M2 | |

3 | Line color | Sheet metal Warm gray IC, aluminum alloy type steel body color | |

4 | Import voltage | 200VAC ± 5%, 50 / 60Hz, ground protection, import capacity ≤ 10KW (including welding machine) | |

5 | Air source | 0.4-0.6Mpa, dry, no oil, filter, clean air used, flow rate approx. 300L / min | |

6 | Line SPM | ≧ 100pcs / min | |

7 | Product pass rate | 99% (excluding defective raw materials and human intentional causes) | |

8 | Line failure rate | ≤2% (own cause of equipment) | |

9 | Line main spare parts | Air Cylinder: Airtac, LM Guide: HIWIN / TBI | User can be specified |

Ten | Line usage environment | Can be used in general factories, avoid corrosive gas and prevent dust |

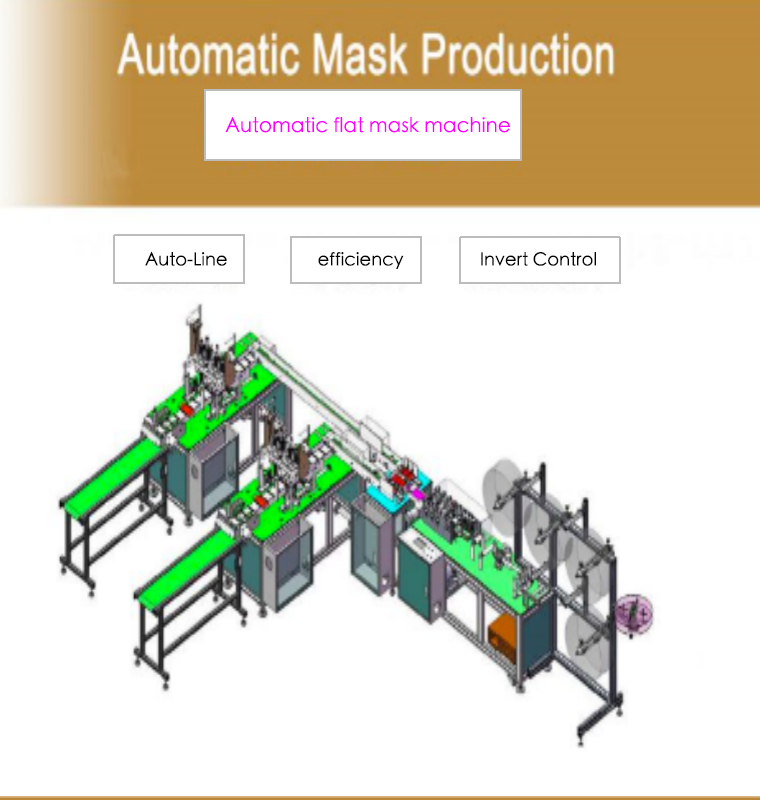

The non-woven mask manufacturing machine is a fully automatic production line consisting of one mask body molding unit and two ear strap welding units that employ ultrasonic fusion.

The mask body molding unit performs auto-feeding of raw materials (nonwoven fabric), nose wire insertion, cutting, pleating, edge welding, etc. There are two types of ear strap welding units, which can be selected depending on whether the ear strap is welded outward or inward to the mask body.